Process steps of making Buddhist incense

First preparation ingredients: Xianxiang is the fragrance without bamboo core, commonly known as zhitiaoxiang, Caoxiang and Xianxiang. Mainly wood flour or carbon powder, sticky powder (elm bark powder or corn starch), essence, pigment (commonly used rosin, red, yellow, green, gold powder, etc.) and help and other information (quality of progress may reduce costs, producers add some trace items, such as Ling powder, gold tablets, calcium carbonate, potassium nitrate and other components, see the formula.

Second sieve powder: the wood powder, sticky powder and carbon powder in the incense making materials sometimes contain small pieces of wood, gravel, iron slag and other impurities. It is easy to break and even form the phenomenon of fire break. In the production line, it is easy to block the discharge port, damage the mold or form the phenomenon of uneven discharge, deformation and broken material. Sift the raw data to remove impurities in the powder to ensure the data in order. This is the main process of aroma making (this process is completed by the screening machine)

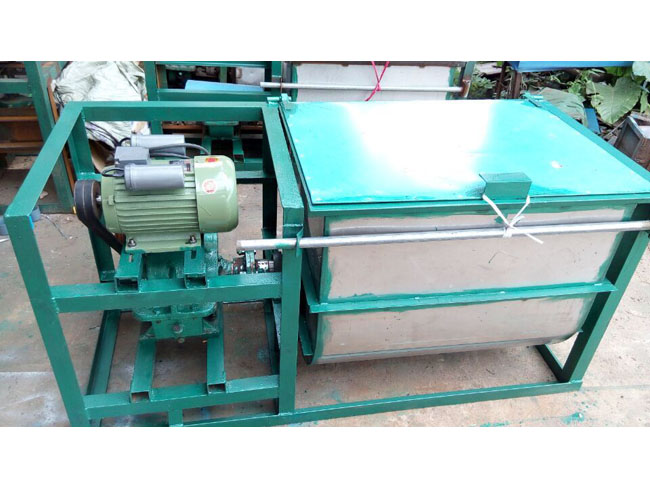

Three mixing: mixing is very important in the whole process of aroma making, which needs experience: 1. Make sure to mix the information evenly before adding water. 2. The mixing time is about 20-45 minutes. 3. Put all kinds of raw materials and water into the blender according to the proportion (special stainless steel liner, so as to make the data color evenly, not to change color, and not to damage the viscosity of spices). There should be no air in the material, and the air will break the stick during the extrusion process. 4. Before mixing, impurities should be removed, the proportion should be appropriate, the moisture content should be appropriate (too dry, easy to crack, too wet, easy to deform), and the mixing should be uniform. (this process is completed by flour mixer)

Four starts: this process is completed by the fragrance machine. Put the mixed material into the inlet, insert an iron bar into the cylinder to exhaust before starting, and turn off the air switch after discharging. After being pressed by the hydraulic device, the spice material is extruded from the die hole and becomes the required shape. The holes in the mould (as shown in the figure) are arranged in rows, with one row, two rows or more rows of holes. Most of them use two rows of holes. Therefore, the extruded sticks are also placed in rows, neat and not easy to deform. (this process is the central process and is completed by the fragrance making machine)

The remaining step is to dry or dry the produced incense, and then the finished product can be packaged and shipped.

Article source: Xinhui automatic incense making machine

-

12-24

What are the common flavor pigments?

At present, the main stream incense making machines in the market are elegant in appearance. They choose the machines with active feeding, active tail cutting and active label wearing. However, some of the low-quality machines have many disadvantages. The demand for products is very strict, and the proportion of ingredients can not be too poor. Moreover, the noise is very loud, and the maintenance is very troublesome. In the same way, there are higher requirements for the selection of pigments u

-

12-24

How long is the service life of Guangdong automatic incense making machine?

As we all know, the automatic incense making machine is a new type of incense making machine. Compared with the traditional machine, the automatic incense making machine has the advantages of convenient operation, high production power and cost saving, which is in line with the development trend of modern industry. The venture capital, risk and income of the fragrance making industry are small, and it is a good project for many people to start their own business. But how to choose a better fragr

-

12-24

Labor saving principle of Guangdong automatic incense making machine

It has always been the policy of the full-automatic fragrance machine manufacturers to produce good spices without labor. After a long time of discussion, it is found that good spices require a lot of manual procedures and long-time equipment operation. It is far fetched to produce good spices, which greatly affects the power presented, and improves the speed of aroma production for the corresponding market demand This paper introduces a kind of labor-saving manufacturing method of incense makin

-

12-24

What are the types of incense machine equipment?

In other words, the swing incense making machine looks like a baby's cradle with many holes in the center. Appearance specification: length 80cm, width 60cm, height 100cm, weight about 100jin, input power 220 v. The speed changes from 1400 rpm to 70 rpm. There is a simple switch, a craft to do incense, artificial powder, machine swing. Cutting down the artificial rubbing powder can reduce part of the physical strength of the workers, but the effect is not obvious. The labor-saving perfume making